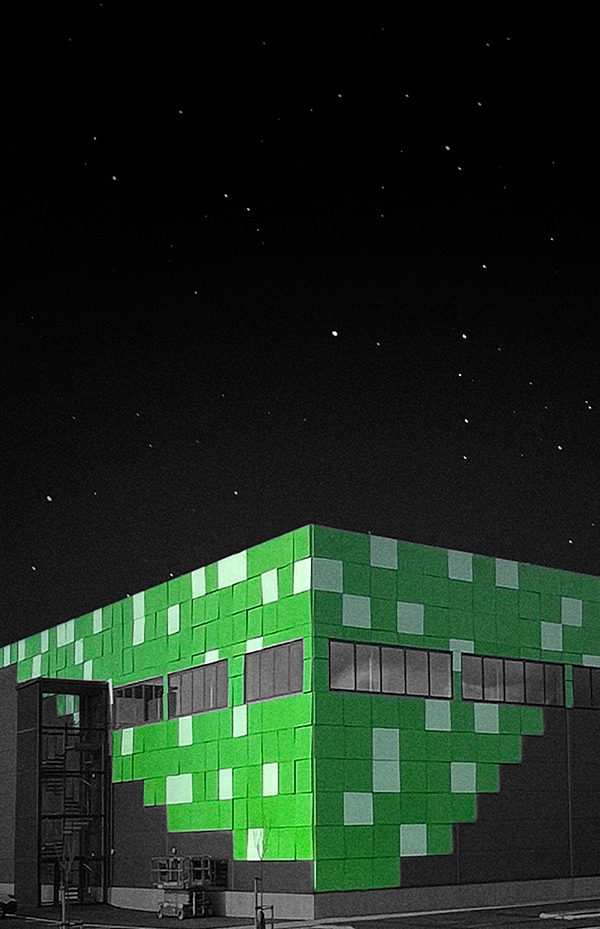

A center for sustainable, healthy food production

Greenfood’s new facility and head offices goes under the name “Greenhouse” for a wide number of reasons. Here, just about everything’s been planned and built with sustainability in focus. The thorough process includes not only the building itself; the building’s surroundings are also part of the program.

The 44,000m2 Greenhouse will act as a production facility, distribution center, innovation center and main offices – a way to centralize and streamline operations, in just about any way possible. The centralization of distribution and handling is in itself a way to reduce climate impact, optimizing logistic flows enough to reduce transportation CO2 emissions with up to 190 tons. Additionally, in collaboration with Elonroad, Öresundskraft and the Faculty of Engineering at Lund University, we’re installing a scalable concept for charging heavy vehicles.

The solution is aimed at facilitating the electrification of our fleet by providing smart and climate-friendly charging infrastructure. This, in turn, will help enable time-efficient transport and a high degree of utilization of the vehicle fleet.

“By bringing several parts of the business – purchasing, product development, processing, production, packaging, storage, distribution and offices – under the same roof, we can reduce logistics and transport, which in turn reduces the environmental impact,” says Lisa Isakson, head of sustainability at Greenfood.

A comprehensive mindset

But these are but a few features among many that stand as proving points to Greenfood’s commitment to a sustainable business. The mindset has had an impact on every part of the construction, from the choice of material to extra insulation in walls and ceiling and a circular use of the heat generated by cooling facilities to heat water and the premises.

“Since our core business is all about green and sustainable food for both people and the environment, it’s natural for us to try to work with sustainable solutions in our facilities and transportations as well, says Lisa Isakson.

In line with this ambition, a 33,000 m2 solar panel will cover some 25% of the facility’s need, which will help minimize the operation’s footprint.

Reuse and use material with a lower climate footprint

The materials chosen for the construction have all been chosen for their low climate footprint. For example, we’ve chosen to work with “green asphalt” – asphalt that consists of large amounts of recycled material, manufactured in plants powered by fossil-free fuel. We’ve also chosen to use “green concrete” – concrete with a high concentration of slag, which means its climate impact is significantly reduced. Additionally, we’ve managed to reduce the amount of concrete needed by opting for thinner slabs.

Overall, the philosophy of reusing has been applied in everything from asphalt to rebar and interior details. And when it comes to the interior, we’ve gone over and beyond in terms of isolation to minimize heat waste, even reusing, and repurposing the heat generated from our cooling plant.

The trees and the bees

But not only the building is part of the ambition. The surrounding areas are just as much a part of the sustainability strategy. A large variety of trees, shrubs and meadow flowers are planted to benefit biodiversity and provide food and habitat for a wide number of species. There’s also an area specifically designated for wild bees.

“Even though our fruits and vegetables won’t be grown here, we are making an effort to help the insects and pollinators that are absolutely essential to much of what we eat,” says Lisa Isakson. “I hope this can inspire other green building projects, not only when it comes to material selection and energy solutions, but in a larger perspective where ecosystem services and greenery in the surroundings are just as important.”

We’re true believers in all things sustainable. Are you?

When it comes to sustainability, we put our money where our mouth is. That’s why we’ve structured our work towards a healthier tomorrow into different focus areas and strict goals. And you’re free to explore them.